Facade cladding

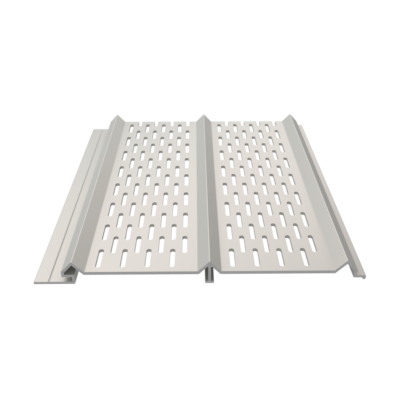

Falkit® is a coating system for all types of surfaces based on tongue-and-groove aluminum slats. Its simplicity of assembly, variety of slats and adaptability give it great versatility, being able to adapt to multiple applications: ventilated facades, canopies, fairings, interior coverings, decorative panels, property enclosures, etc.

Its simplicity of assembly, variety of slats and adaptability give it great versatility, making it suitable for multiple applications:

- Ventilated facades

- Canopies

- Fairings

- Interior coverings

- Decorative panels

- Estate enclosures

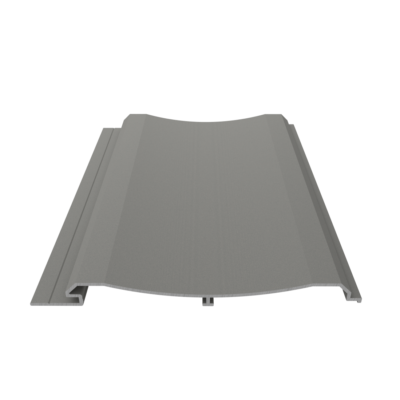

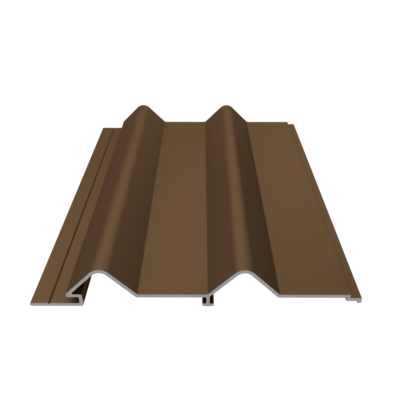

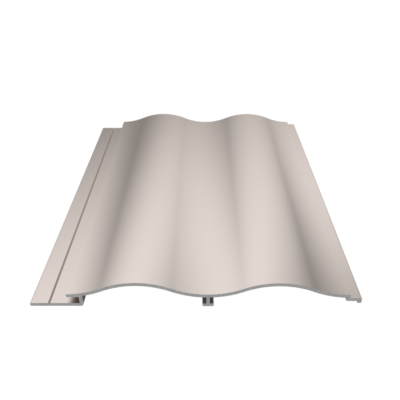

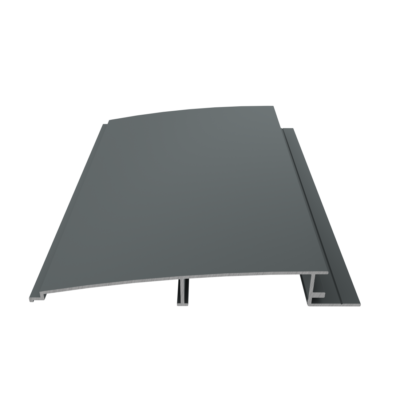

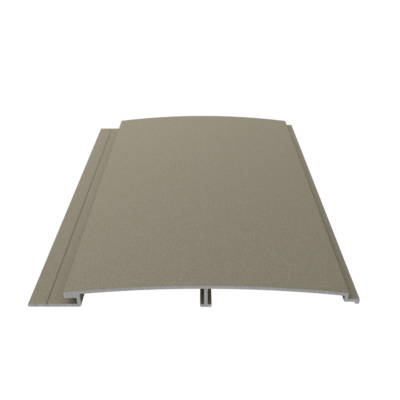

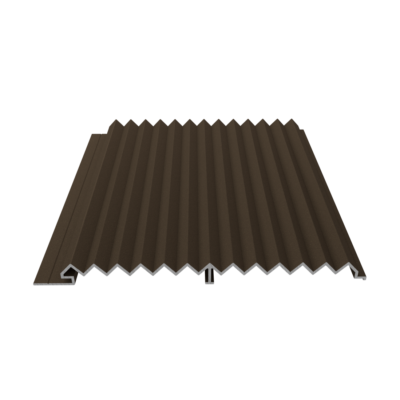

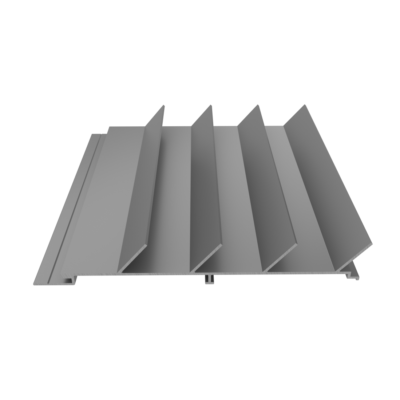

The wide range of slats that make it up, the different mounting options, the possibility of combining different slats and the multiple finishes give the system incalculable possibilities of use.

In addition, Alu-Stock has the ability to create new slat designs for certain specific works that require it due to their uniqueness.

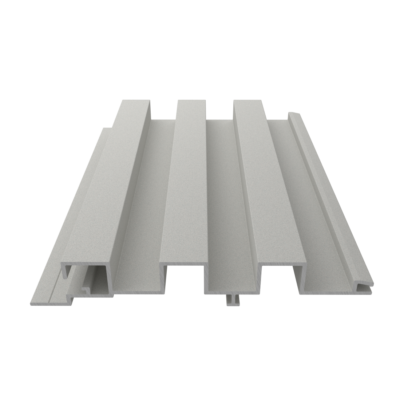

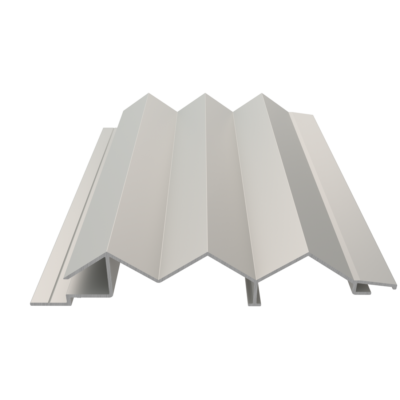

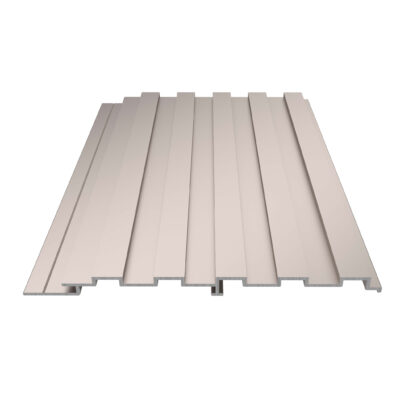

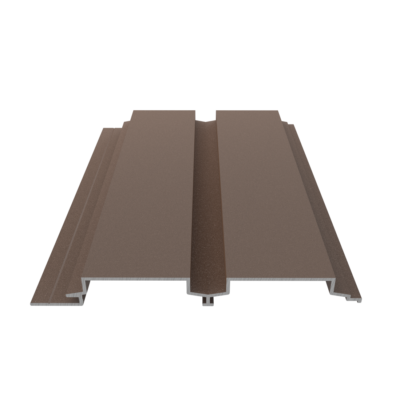

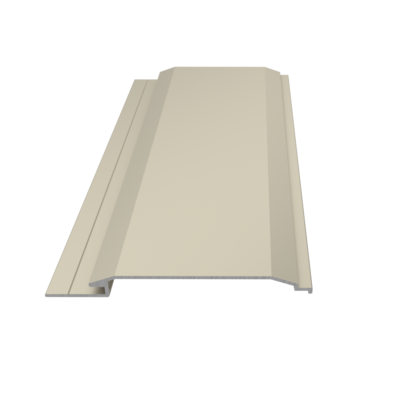

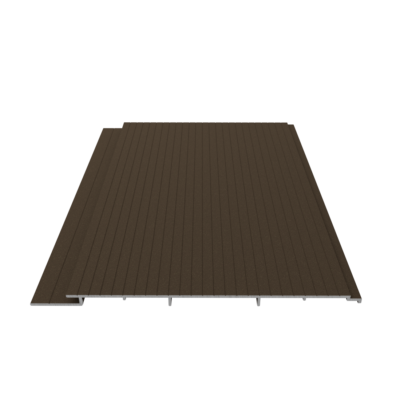

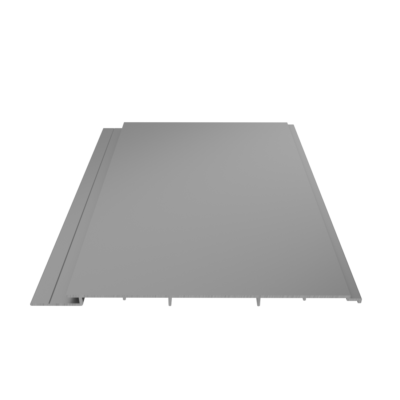

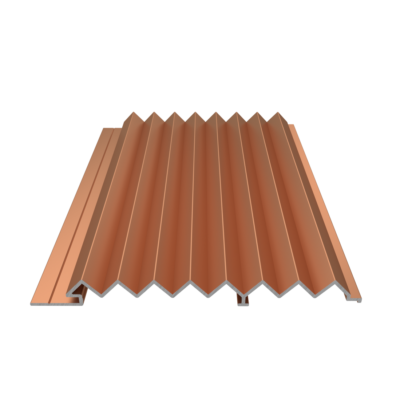

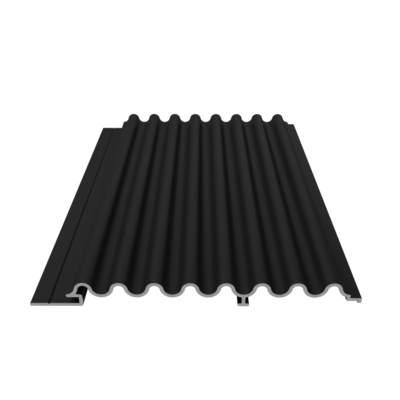

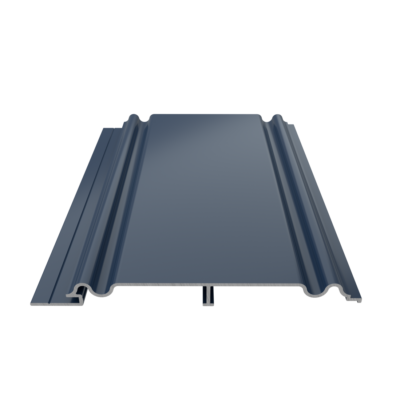

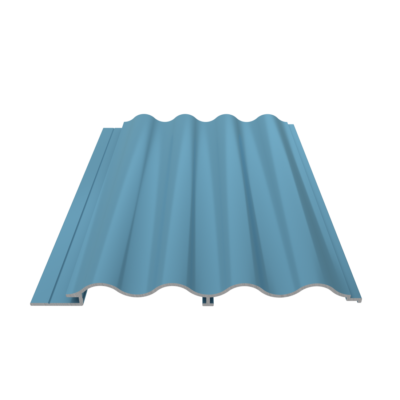

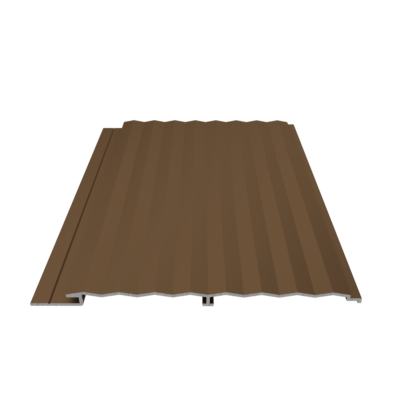

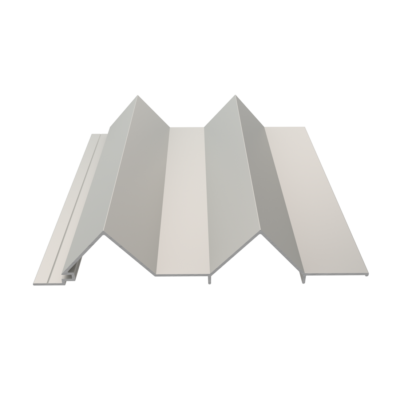

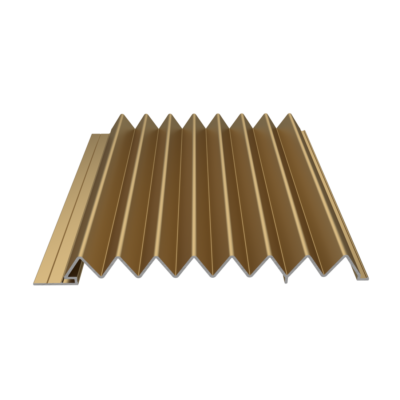

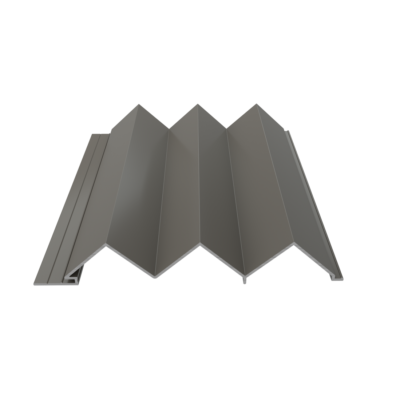

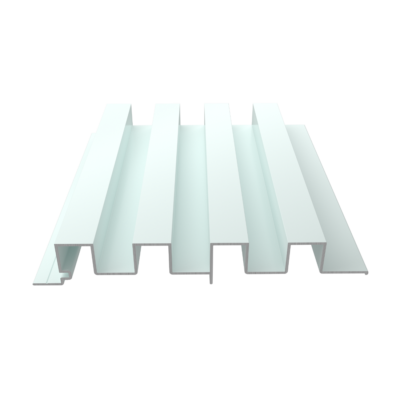

Range

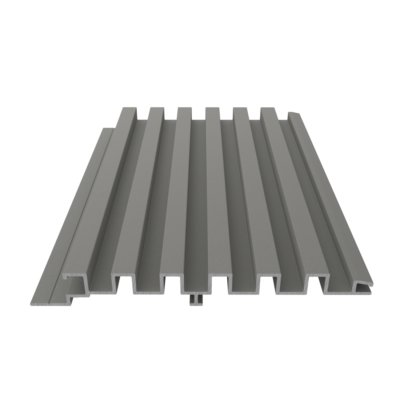

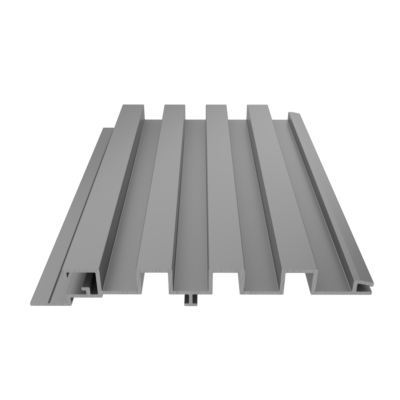

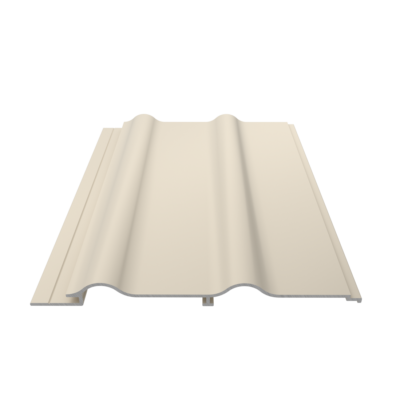

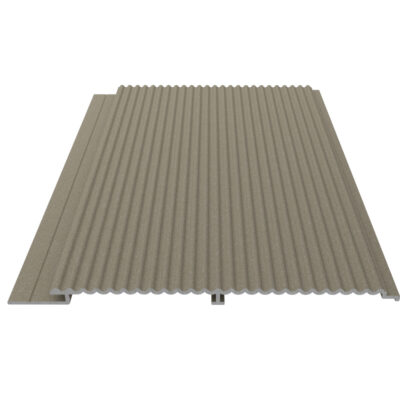

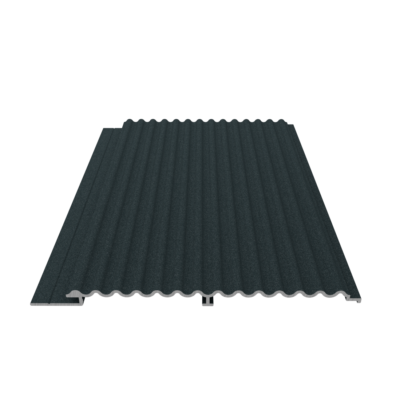

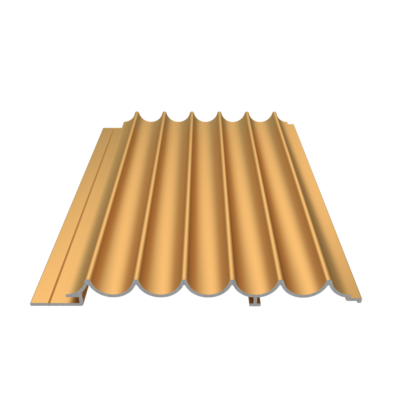

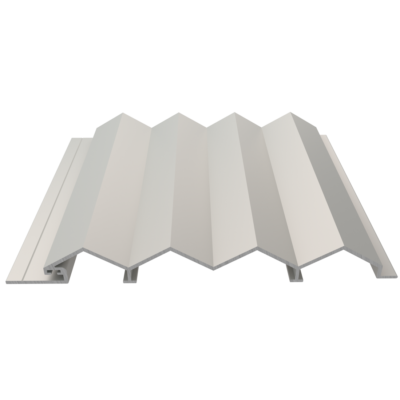

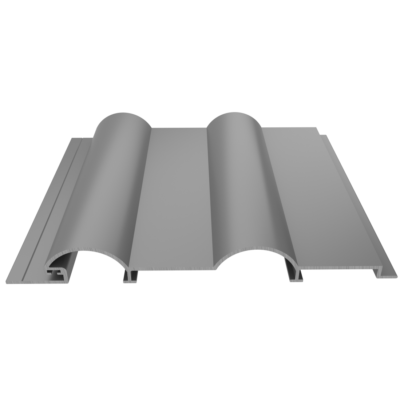

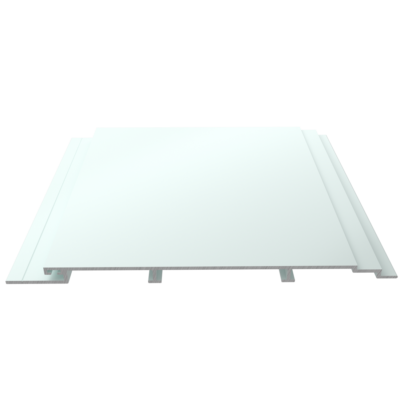

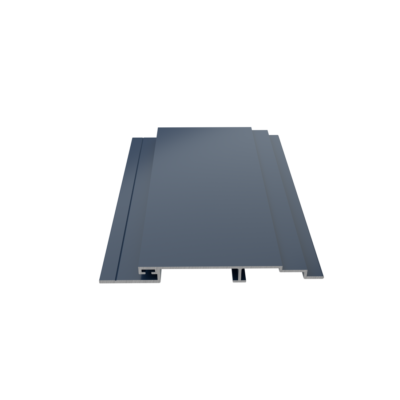

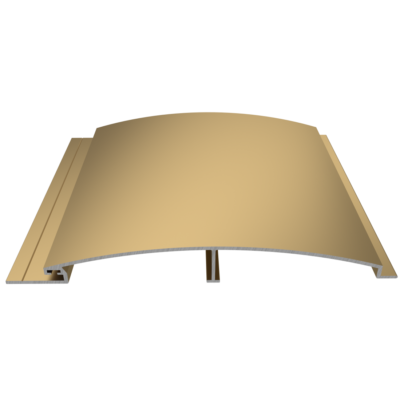

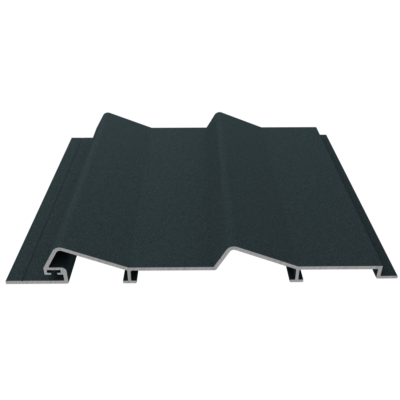

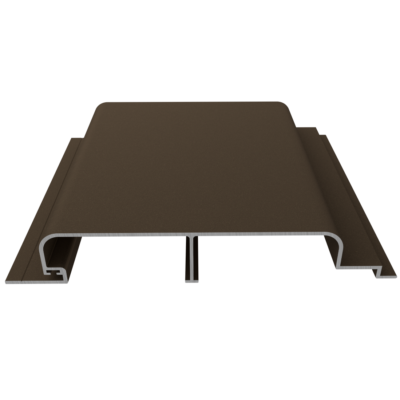

The Falkit® System has more than 40 slats divided into the following series, apart from the existing finishing profiles.

Possibilities

The great diversity of slats, together with the possibility of combining several of them with each other, allows for countless

final finishing designs, thus achieving great versatility.

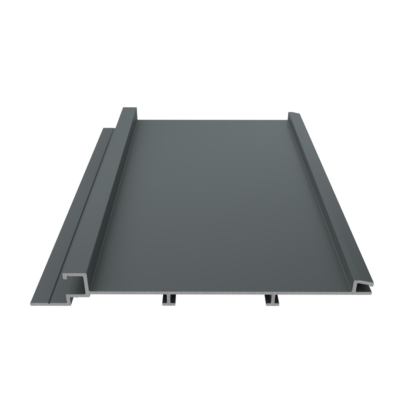

The possibility of installing both large and small cloths, as well as the combination with

Other materials allow the Falkit® System to be used for any type of coating.

As a ventilated façade or as a continuous tubeless coating, its versatility allows it to be installed in both exterior and interior projects.

Its great modularity allows it to be installed vertically, horizontally and inclined. Also, depending on the slat, it supports curved installation.

Finishes

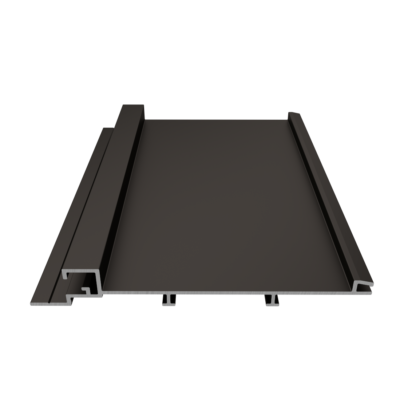

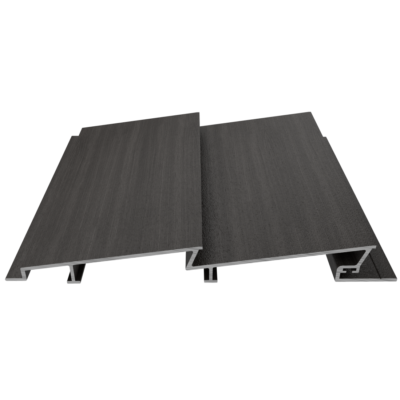

The Falkit® System slats can be presented in three different finishes. On the one hand there is the raw manufacturing finish and on the other hand there is the anodizing and lacquering.

Lacquered

Polyester powder paint coating with a layer thickness between 60 and 80 microns, whose colors are within a wide range of RAL colors, both matte and gloss, as well as textured.

For cleaning, products that are as neutral as possible should be used, avoiding basic or acidic products as well as abrasives, etc…

Anodized

Anodizing is a chemical process through which the layer of aluminum oxide that, by nature, covers the slats, is artificially increased. This increase in thickness achieves, on the one hand, increased protection against corrosion and, from an aesthetic point of view, creates a more uniform finish in color and tone.

installation

The simplicity of its installation method, as well as its modularity and the low weight of the slats allows for quick transportation, handling and installation of the system, contributing to overall cost savings for the coating.

Substructure

The ECP substructure is designed for installations that require insulation and a ventilated chamber. Depths of up to 150 mm can be reached. The anchoring bracket with tab allows adjustment of the batten before its final fixation.

Maintenance and cleaning

Aluminum is a material that requires minimal maintenance and is very simple. Below are the cleaning and maintenance recommendations based on its finish to maintain a finish and performance that lasts over time.